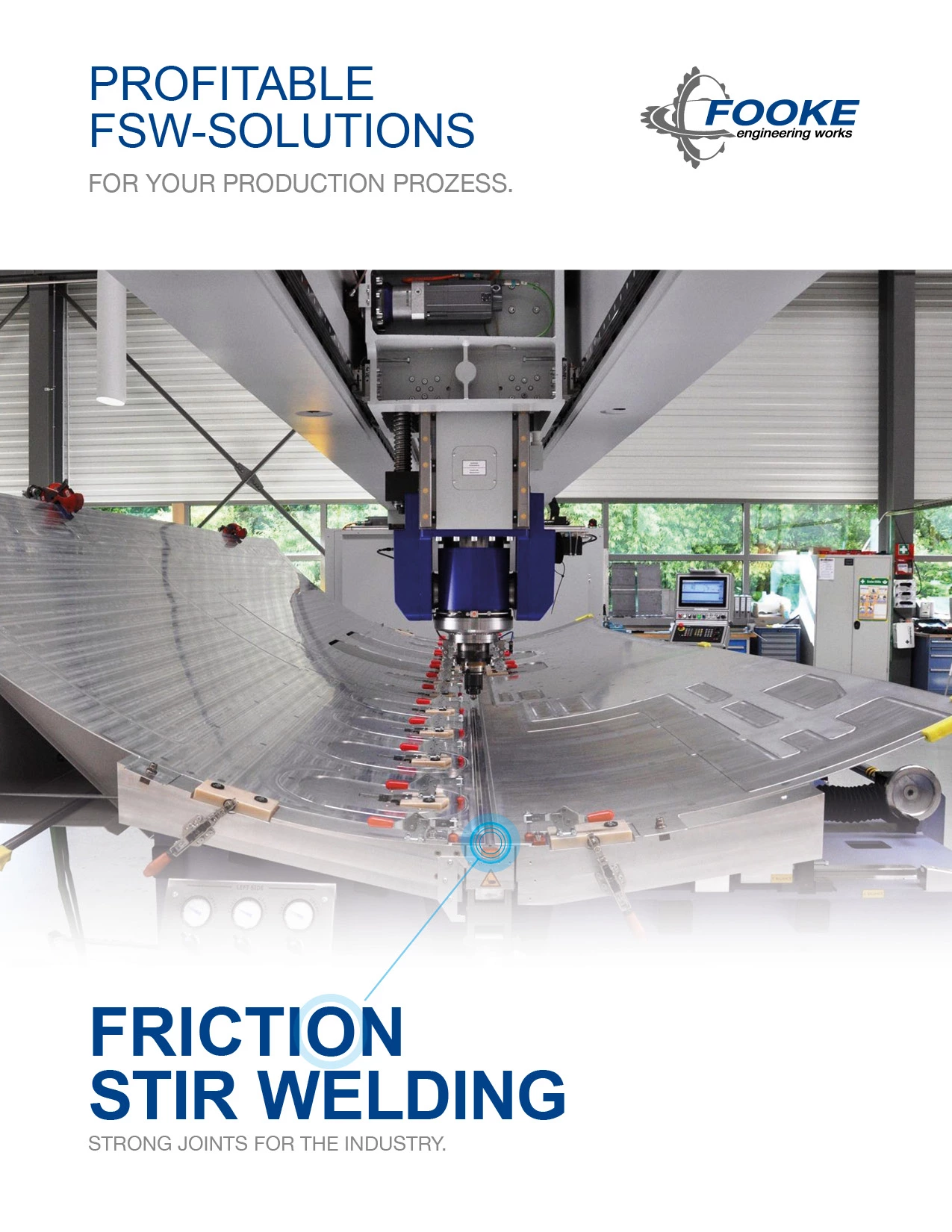

FSW Machines

Strong joints for the industry - with modular FSW machine systems, we supply you with reliable FSW complete solutions for automated production.

YOUR BENEFITS AND WHY FOOKE FSW MACHINES ARE THE BEST CHOICE!

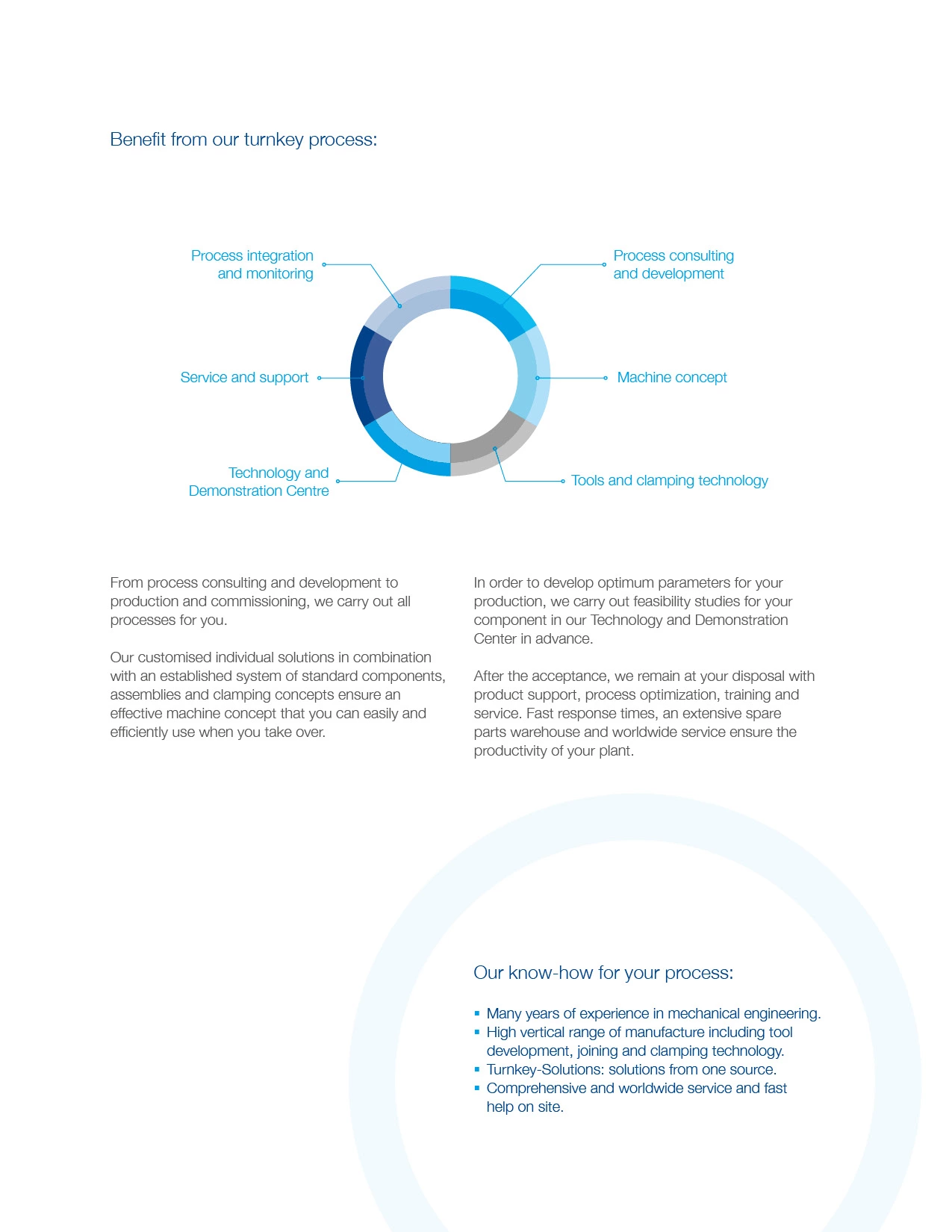

Our know-how for your process:

- Many years of experience in mechanical engineering.

- High vertical range of manufacture including tool development, joining and clamping technology.

- Turnkey solutions from one source.

- Comprehensive, worldwide service and fast help on site.

Your advantages at a glance:

- Detailed consultation in advance.

- Intensive exchange with our FSW engineers.

- Modular machine structure enables individual adaptability of the FSW systems.

- Best possible integration into existing production processes.

- High return of investment.

FSW MACHINES IN ACTION

Customer Projects & Applications

Innovative FSW Machines

for the Aerospace Industry

Our state-of-the-art FSW machine (Friction Stir Welding) is specifically designed for the precise and material-friendly joining of large-format aluminum sheets into load-bearing structures such as aircraft fuselages. Based on a proprietary 5-axis FSW process, this advanced welding system ensures exceptional accuracy and reliability.

This cutting-edge FSW technology enables significant weight reduction—up to 1 kg per meter of aircraft length. The result: dramatically lower jet fuel consumption and a measurable contribution to a more sustainable, resource-efficient aviation industry.

Key Advantages of FOOKE FSW Machines for Aerospace Applications

- No Sealants Required – Saves material, time, and costs

- Chip-Free Joining – No drilling chips, no post-cleaning required

- Minimal Tool Wear – Extended tool life and reduced maintenance

- Lower Energy Consumption – High efficiency even with large components

- Improved Aerodynamics – Smooth, flush weld seams for reduced drag

- No Rivet Head Wear – Maintenance-free welded connections

- Elimination of Titanium Fasteners – Additional weight savings

- 100% Recyclable Longitudinal Seams – Ideal for lightweight construction

- Reduced Fuel Consumption – Economic and environmental benefits

FOOKE’s FSW machines are redefining the manufacturing of lightweight structures for the aerospace industry—precise, efficient, and future-ready.

Double-Gantry FSW Machine FSW 50

Commercial Vehicle Manufacturing

When joining truck longitudinal beams, floor panels, and side components, the FSW 50 stands out with exceptional process reliability, minimal component distortion, and a significant increase in production efficiency. With two independently controlled gantries and three separate work zones, this advanced FSW machine enables parallel processing of multiple workpieces—drastically reducing cycle times while maintaining consistently high weld quality.

Key Highlights of the FSW 50 – Your Advanced FSW Machine for Heavy-Duty Applications

- Ultra-Stable Machine Structure – Maximum rigidity with minimal deflection, even under high load

- High Dynamics and Feed Rates – Perfectly suited for long, large-volume components

- Dual Gantries, Triple Work Zones – Enabling parallel manufacturing and optimal machine utilization

- Designed for Commercial Vehicle Manufacturing – Tailored FSW processes for truck chassis and structural parts

- Accelerated Production Workflows – Shorter cycle times and increased throughput

- Low-Distortion Welds – Reduced rework and improved dimensional accuracy

- Material and Energy Efficient – No filler materials, no welding fumes

- Fully Automatable – Seamless integration into existing production lines

With the FSW 50, FOOKE delivers a highly versatile and powerful FSW machine engineered specifically for the demands of commercial vehicle manufacturing—combining flexibility, performance, and maximum production efficiency.

Floor panels, sidewalls and roof sections

Railway Industry

FOOKE FSW machines are successfully used for joining aluminum profiles in the production of rail vehicles—including floor panels, sidewalls, and roof sections. In this demanding sector, our machines deliver exceptional process stability, precise weld seams, and maximum production efficiency—even for deep weld joints.

Thanks to advanced machine technology, our FSW solutions enable weld depths of up to 100 mm while maintaining consistent seam quality and reproducible process reliability.

Technical Advantages of FOOKE FSW Machines for Rail Applications

- Outstanding Machine Rigidity – Minimizes deflection for stable welding processes

- Shorter Processing Times – Enabled by high dynamics and optimized motion control

- Fully Automated Process Monitoring – Ensures continuous quality assurance and complete documentation

- High Weld Quality – Even with large, high-volume aluminum profiles

Smart Clamping Technology for Maximum Process Security

Our custom-engineered clamping systems ensure reliable fixation of large-format aluminum components—even with complex geometries. This guarantees consistently high weld quality with maximum repeatability.

Whether for floor panels, sidewalls, or roof sections—FOOKE FSW machines are the ideal solution for producing highly durable, precise welded joints in modern rail vehicle manufacturing.

Custom Clamping Systems for Maximum Process Reliability

Railway Industry

A stable and repeatable FSW process starts with the right fixturing. At FOOKE, we design customized clamping systems tailored precisely to your part geometry and process requirements—ensuring the ideal foundation for high-performance FSW machines.

These specially engineered fixtures guarantee accurate positioning and force-locked clamping of workpieces—even for large or complex aluminum components.

Your Key Advantages at a Glance

- Maximum Process Reliability – Secure, distortion-free fixation of components

- Consistent Weld Quality – Independent of part size or production volume

- Reduced Post-Processing – Stress-free and dimensionally stable joints

- Fast Setup Times – Ergonomically designed, process-optimized clamping solutions

With our custom clamping systems, FOOKE provides the foundation for high-quality, cost-efficient, and fully automatable Friction Stir Welding (FSW) production—engineered to meet your exact needs.

INDUSTRIAL-GRADE JOINING SOLUTIONS

FOOKE FSW Machines for Maximum Strength and Precision

Quality „made in Germany“:

this philosophy is consistently followed by FOOKE.

You are a partner of the industry and are facing the challenge of reliably welding large components in constant quality? In that case, the technology of friction stir welding supplies you with the key advantages.

With modular machine systems, FOOKE offers process reliable overall solutions for the automatic manufacturing. We use our know-how and experience as long-time manufacturer of gantry milling machines and from numerous applications in the railway technology, the automotive and the aerospace industry, for the development of innovative machine concepts in the field of FSW.

From individual FSW systems up to a completely new interlinked manufacturing process, we supply overall FSW solutions for the industrial series production. Many years of experience in mechanical engineering, joining technology and our high in-depth production translate into efficient machine concepts, specially tailored to your needs.

Our turnkey solutions guarantee an optimized productivity and a high level of safety and reliability – worldwide. Discover new markets with our innovative FSW solutions!

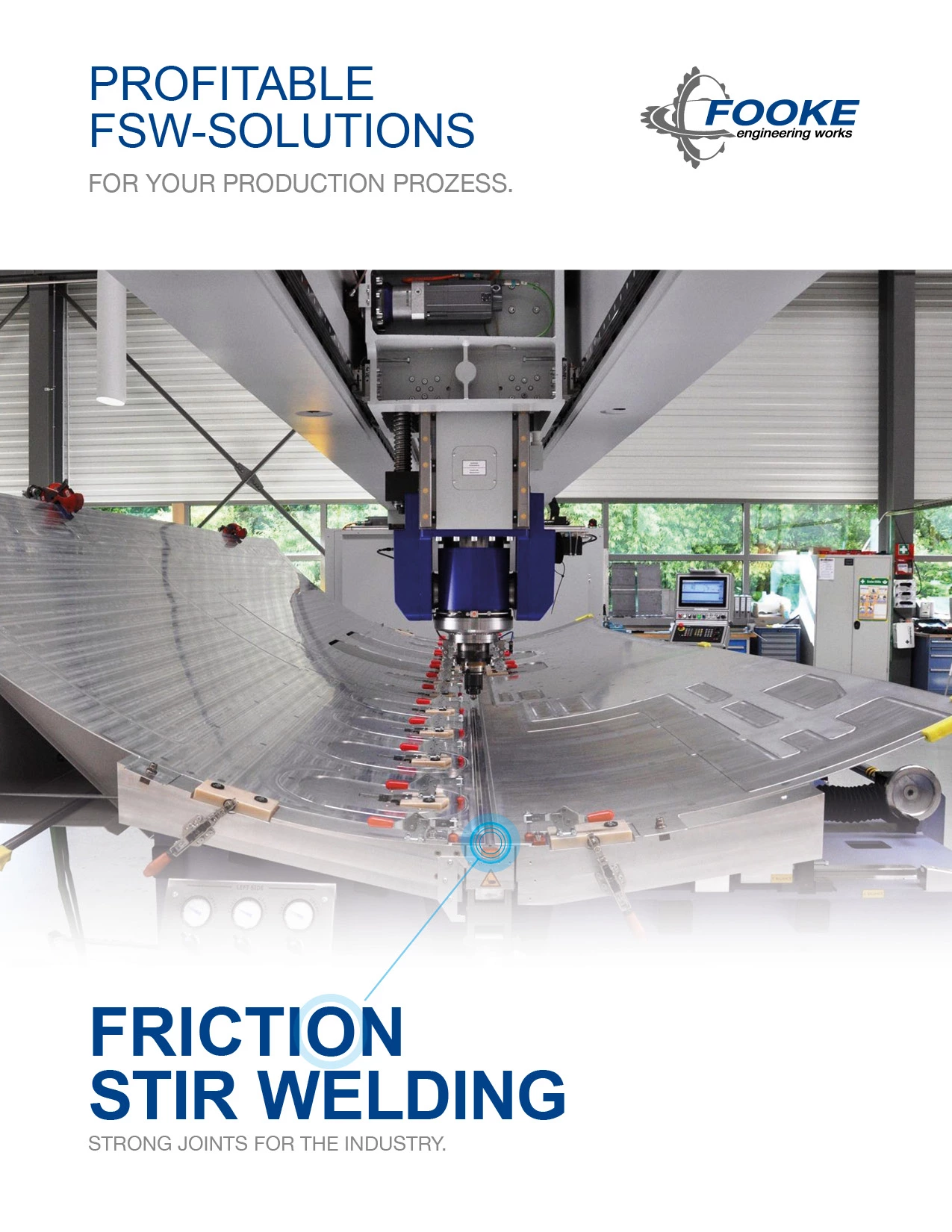

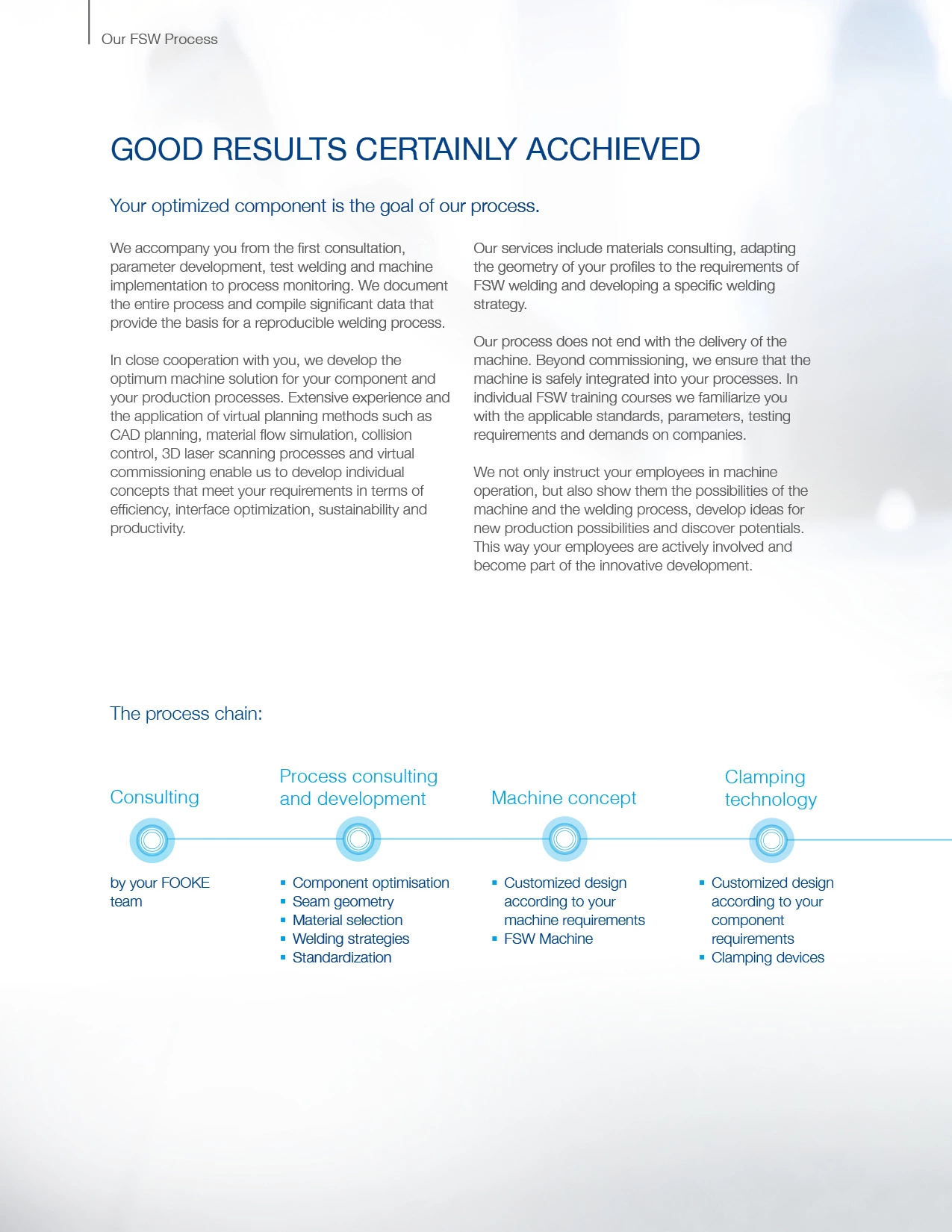

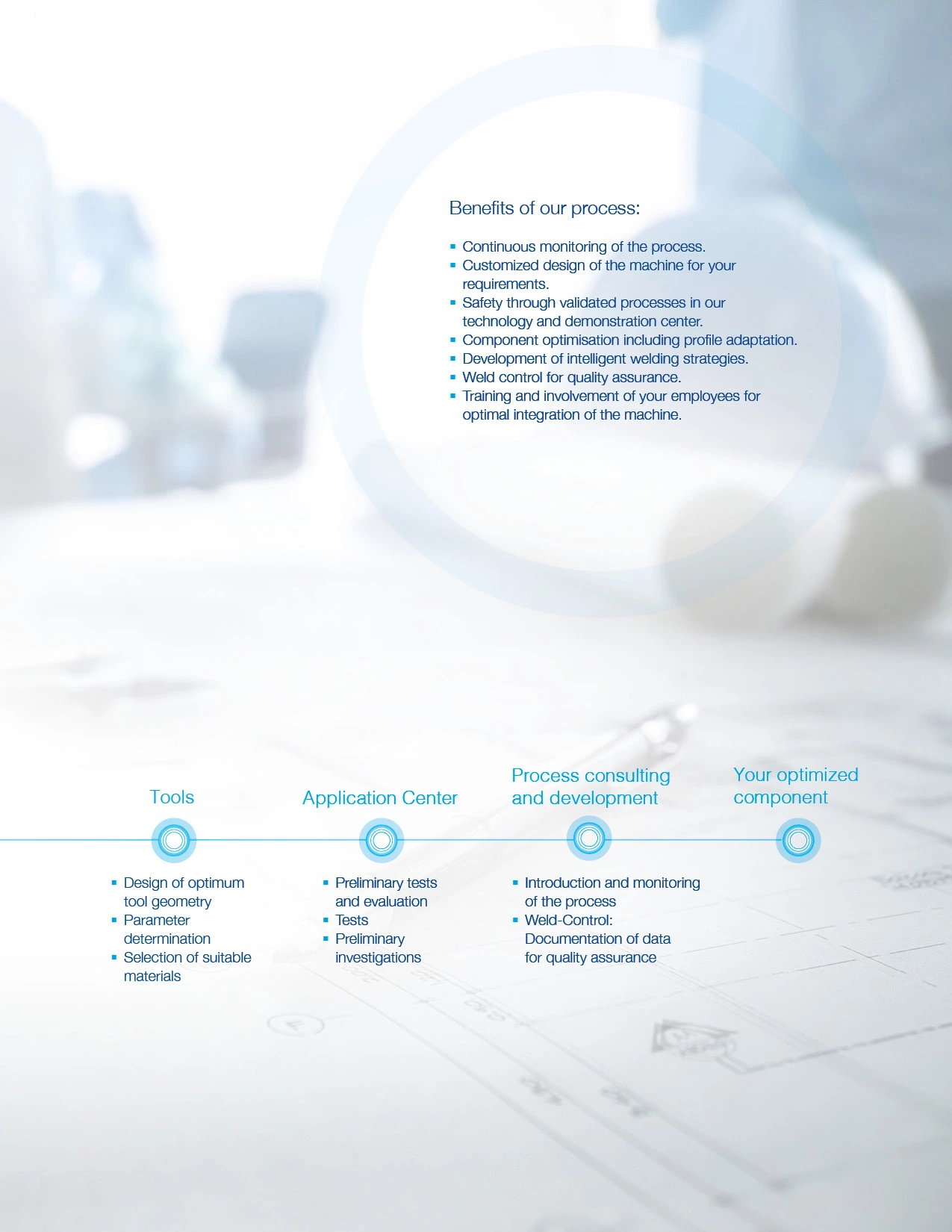

From process consulting and development to production and commissioning, we carry out all processes for you.

Our tailor-made individual solutions in combination with an established system of standard components, assemblies and clamping concepts, ensure an effective machine concept that you can easily and efficiently use use when you take over.

For optimum parameters for your production, we conduct feasibility studies for your components in our Technology and Demonstration Center in advance.

After the acceptance, we are at your disposal with product support, process optimization, training and service. Fast response times, an extensive spare parts warehouse and worldwide service ensure the productivity of your plant.

NO OFF-THE-SHELF FSW MACHINES – EVERY SYSTEM IS TAILORED TO YOUR NEEDS

At FOOKE, you won’t get a standard FSW machine. Each system is precisely engineered to match your individual production environment and specific process requirements.

Your Custom FSW Machine – Designed Around Your Production Process

At FOOKE, we don't just deliver FSW machines—we develop tailor-made solutions built around your specific production needs. Before we begin engineering your customized Friction Stir Welding (FSW) machine, we work closely with you to analyze your entire production workflow:

- What materials and alloys (e.g., aluminum, titanium) are being used?

- How is your production environment organized—manual, semi-automated, or fully integrated?

- What mechanical requirements and quality standards must your components meet?

This in-depth analysis forms the foundation for your dedicated FOOKE FSW project team—experts who understand your industry-specific demands, whether in aerospace, space technology, shipbuilding, commercial vehicles, or rail manufacturing.

Industry-Optimized FSW Machines for the Highest Demands

Our solutions are precisely engineered to address the challenges of your industry:

- Aerospace – Lightweight, high-strength welds for fuselage and wing structures

- Space Industry – Ultra-precise longitudinal seams for tanks and structural components

- Shipbuilding – Large-scale, corrosion-resistant welds for decks and hull sections

- Rail Vehicle Manufacturing – Stress-free welding of floors, sidewalls, and roof elements

- Commercial Vehicle Manufacturing – Low-distortion welds for longitudinal beams and frame parts

From Analysis to Integration – Your Complete FSW Solution from FOOKE

Only after all key parameters are defined do we begin developing your personalized FSW machine. Throughout the entire project, we maintain close collaboration to ensure maximum precision and seamless process integration.

Our experienced engineering team supports you across the entire lifecycle:

- Planning and design of your FSW machine

- Integration of control systems and FSW-specific software

- Commissioning, training, and a full range of service and maintenance solutions

We deliver a well-thought-out, scalable FSW system—cost-efficient, automatable, and perfectly aligned with your requirements.

Get in Touch with FOOKE

Your Partner for Custom FSW Machines

Have questions about our FSW machines or looking for a tailored solution for your production?

We’re here to help. Please fill out the form below – our team will get back to you promptly.

Phone: 248 - 218 5880

E-mail: info@fooke-usa.com

Download Product Brochure

FREQUENTLY ASKED QUESTIONS ABOUT OUR FSW MACHINES

What is an FSW Machine?

An FSW machine (Friction Stir Welding machine) is a system that enables the joining of metals in a solid state—without melting. It uses a rotating tool that generates heat through friction, softening the material (plasticizing it) and creating a strong, high-quality bond between the workpieces.

Which Materials Can Be Welded Using an FSW Machine?

FSW machines are typically used to weld aluminum and its alloys. However, depending on the machine configuration, they can also be used for materials such as copper, titanium, magnesium, and even certain steels. The suitability depends on the specific application and machine design.

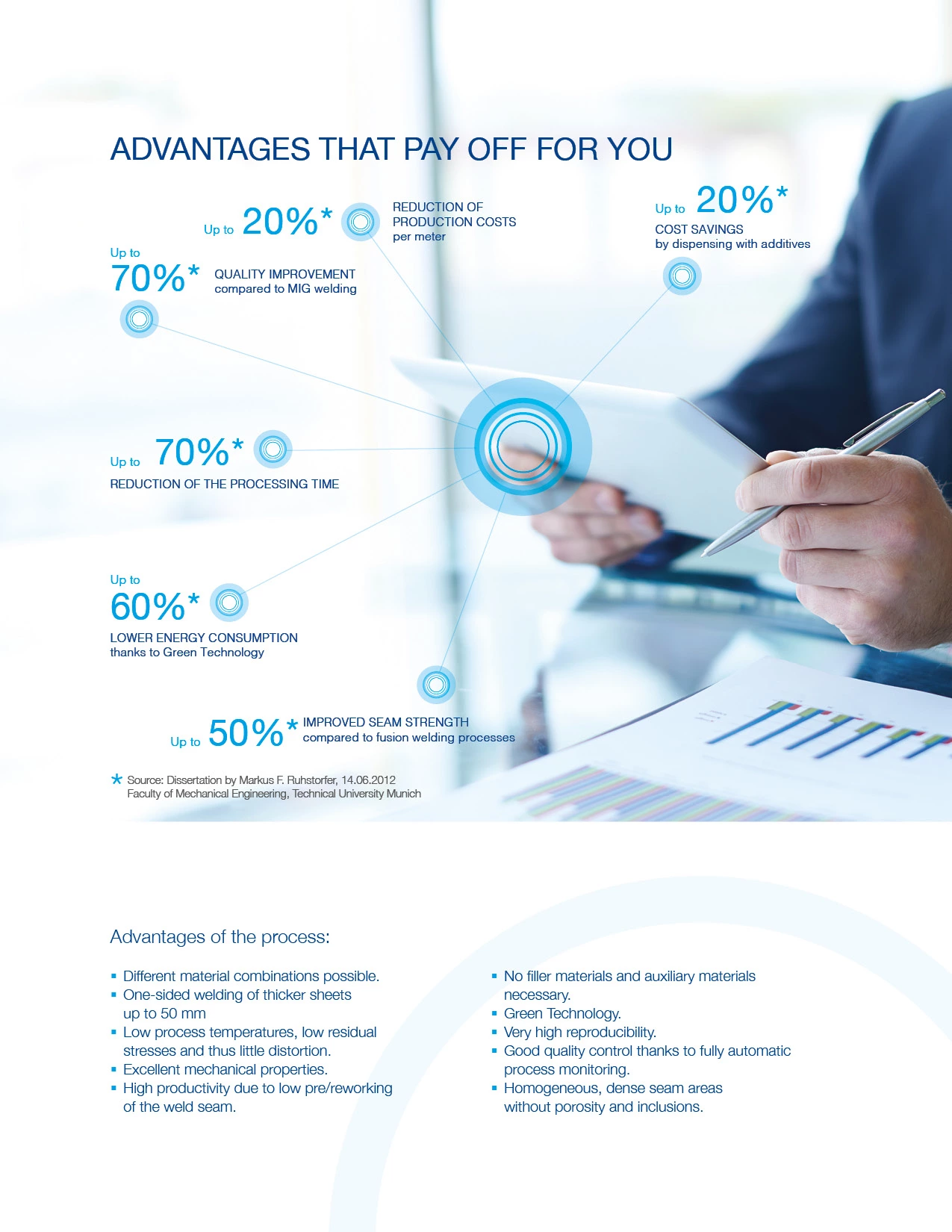

What Are the Advantages of Friction Stir Welding Compared to Conventional Welding Methods?

FSW machines produce high-strength, pore-free welds with minimal distortion—without the need for filler materials or shielding gases. The process is highly energy-efficient and particularly well-suited for thin-walled components and demanding structural joints. This makes it an ideal solution for industries requiring precision, durability, and repeatability.

Where Is Friction Stir Welding Typically Used?

FSW machines are commonly used in industries that demand lightweight yet high-strength metal joints. Key application areas include the aerospace industry, automotive and commercial vehicle manufacturing, rail vehicle construction, and the shipbuilding sector. Wherever durable, precise, and material-efficient connections are required, FSW is an ideal solution.

Does FOOKE Offer Customized Turnkey FSW Machine Solutions?

Yes, FOOKE develops tailor-made FSW machines, ranging from compact systems to fully automated high-volume production lines. We work closely with you to deliver a turnkey solution that fits your exact requirements. Feel free to contact us!

How Is Quality Assurance Handled in Friction Stir Welding?

Quality assurance in FSW machines is achieved through continuous process monitoring, comprehensive documentation of welding parameters, and—if required—non-destructive testing methods such as ultrasonic inspection or eddy current testing. This ensures consistently high weld seam quality throughout the production process.